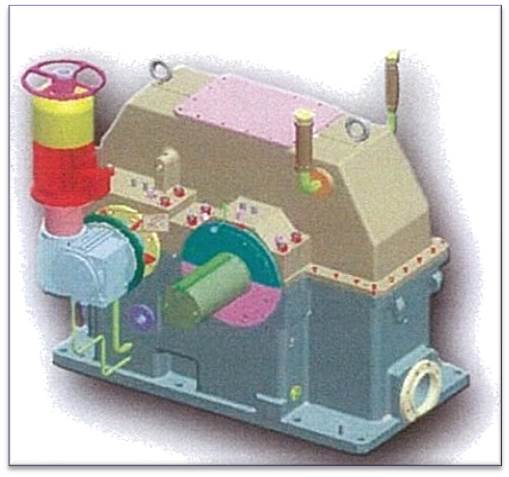

PRO-E MODEL OF GEAR BOX DESIGN STANDARDS / PROCEDURES

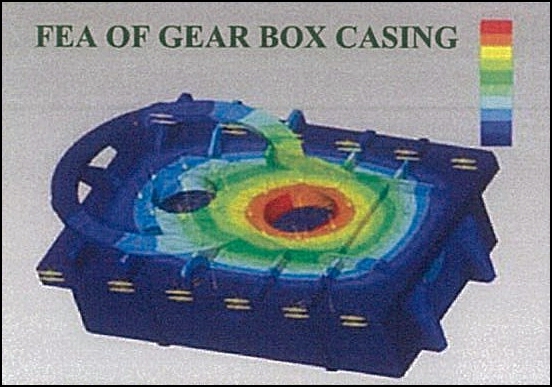

API-613 / API-677 / ISO-6336 / AGMA-6011-H98 / AGMA-6010 F97

API-671 for Couplings / API-614 for Lube Oil system(Out Source approved Vendors)

DIN-3962 For tooth accuracy Balancing Standards - As per ISO-1940-1986(E)/API

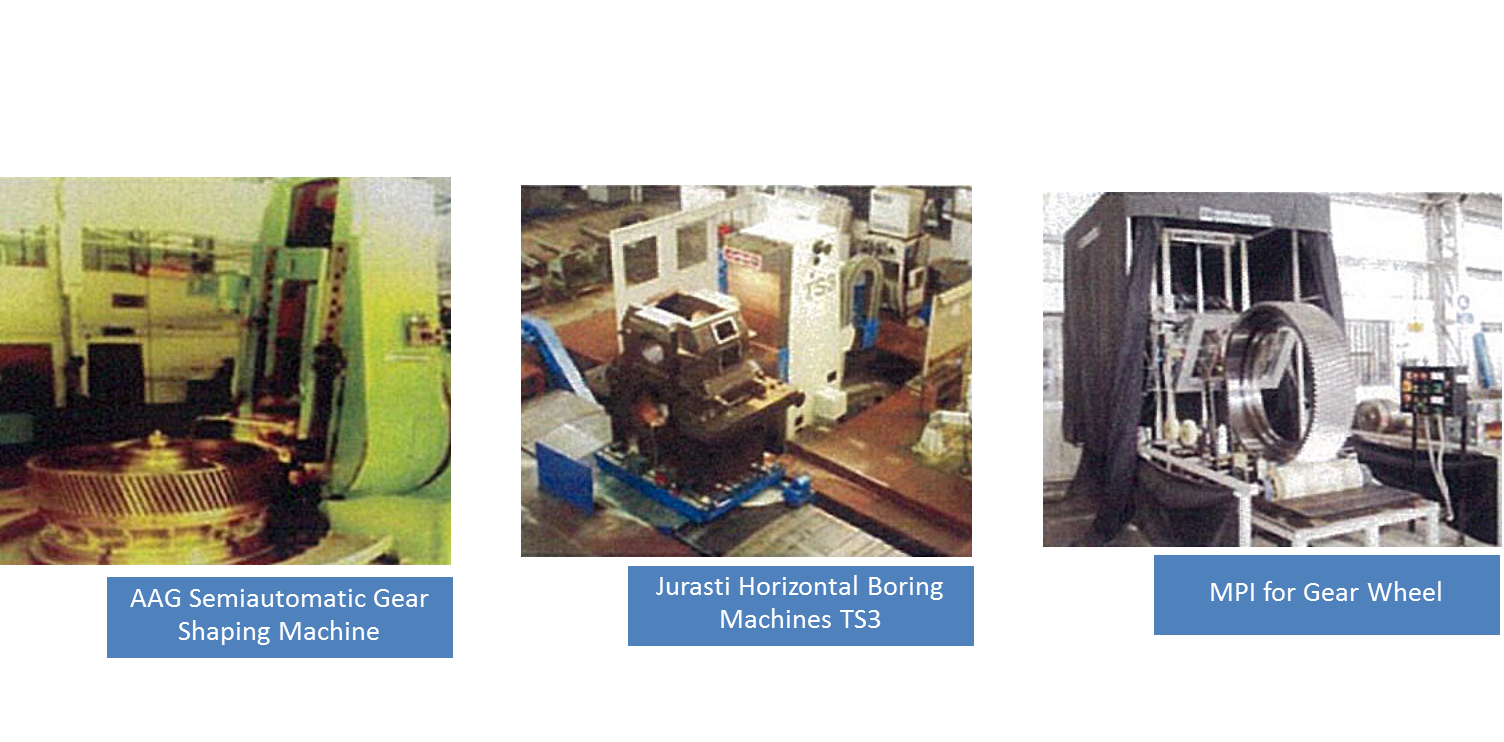

Gleason Pfauter Grinder P1600/2000 G

(Capacity upto dia.2000 mm.)

5 axis CNC Gear Profile Grinder with Siemens 840 D Control

Gleason Pfauter Grinder P1600 G (Capacity upto dia.1600 mm.)

5 axis CNC Gear Hobber with Siemens 540 D Control

Gleason Pfauter Grinder P1600/2000

(Capacity upto dia. 2000 mm.)

Shot Blasing Machine

Max.Diameter : 2,000 mm.dia.

Max.job thickness : 750 mm.

Max.job length : 2,200 mm.

Heat Treatment Furnaces

* 2 Case carburizing, Max job size 2000mm.dia/2000mm.Long Long

*1 Tempering, Max job size 2000 mm.dia

Electrical tempering Facility

Oil quenching facility : 45,000 litrs

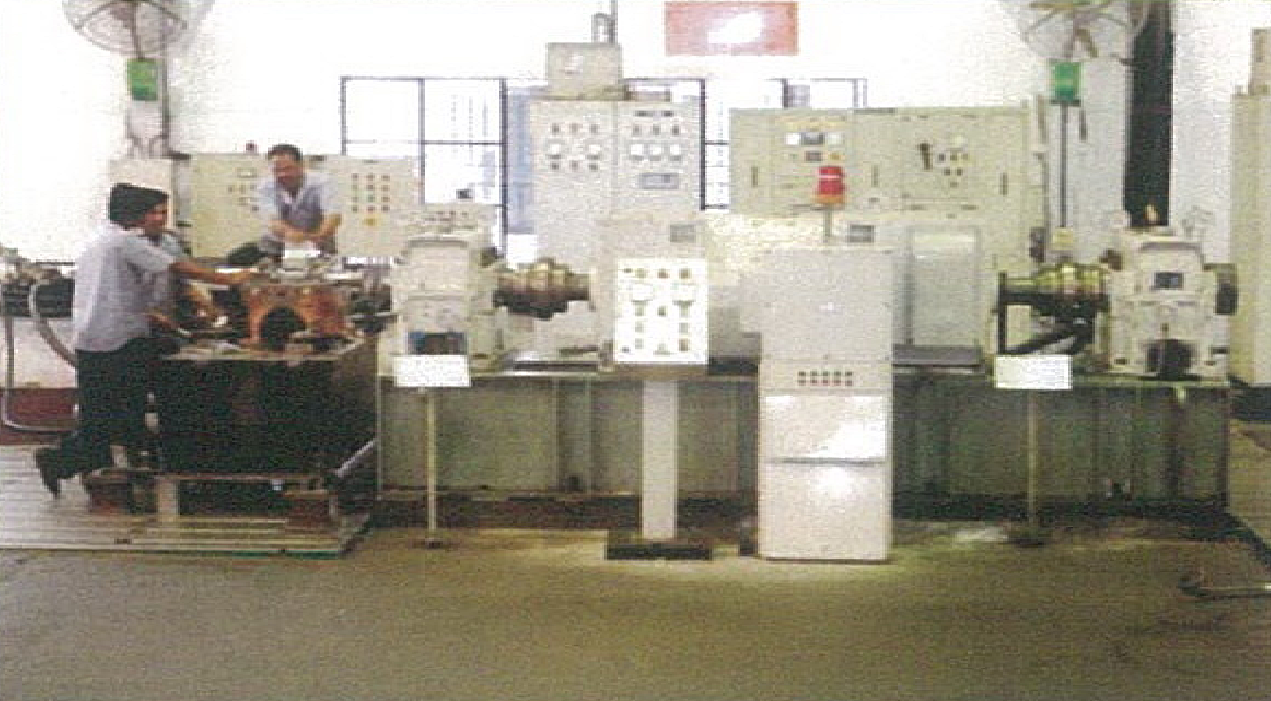

Quality Testing

-1000 kW & 200 kW, DC motor drive Speed increasing slave gearbox for getting input speeds up to 12,000 rpm

-Shop lube system

-Bentley Nevada vibration monitorring system

-ADRE software for shaft vibration analysis (Bode plots and Polar Plots)

-Hand held FFT analyzer for casing vibration and noise